Processing Equipment For Manganese Alloy

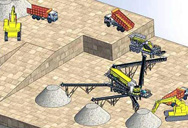

Processing Equipment For Manganese Alloy. As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Manganese Ore Processing Technology and …

Complete equipment for manganese ore beneficiation process Mainly have the vibrating feeder, PE coarse jaw crusher, PEX fine jaw crusher, vibrating screen, bin, pendulum feeder, electro-vibrating feeder, ball mill, spiral classifier, high-frequency screen, mixing tank, flotation machine, concentrator, filter press, filter separator, dryer and so on.

Manganese Processing | Equipment, Process Flow, …

23.08.2019 · The magnetic separators are easy to control, suitable for various manganese ore process. The most commonly used machine is the medium-grain strong magnetic separator, followed by the coarse-grained and fine-grained magnetic separators, the micro-grain-strong magnetic separator is still in the experimental stage.

processing equipment for manganese alloy

processing equipment for manganese alloy biosante. Steel Plate & Sheet American Metal Supplier. Manganese Plate, Heat treatment and other processing operations must be, well as machinery and equipment, these alloy get price

processing equipment for manganese alloy

processing equipment for manganese alloy Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

processing machine for manganese alloy

manganese processing equipment - xsmcrusher manganese processing equipment What is the manganese ore: Manganese is widely distributed in nature, almost all kinds of ores and silicate rocks containing manganese The most common manganese ore is anhydrous and hydrous manganese oxide and manganese carbonate, manganese material now known to have 150 kinds, but the highest manganese…

Processing Equipment For Manganese Alloy In Iran

We have Processing Equipment For Manganese Alloy In Iran,Manganese processing equipment. there is a manganese production line provided by liming in mexico. this production line is the whole manganese process line, which can product 100t manganese per day. liming design all the line and supply pe jaw crusher for primary crusher and hpc cone crusher for secondary crusher.

Manganese alloys - ferroglobe.com

Manganese alloys. We produce different kinds of manganese compounds, mainly for the steel industry. FERROGLOBE OFFERS A WIDE RANGE OF FERROMANGANSE AND SILICOMANGANESE PRODUCTS WHICH BOOST THE QUALITY AND PROPERTIES OF STEEL. More than 90% of the manganese ore mining worldwide goes to producing steel in the form of ferroalloys. What varieties are used? A variety of manganese …

Manganese processing - The metal and its alloys | …

Manganese processing - Manganese processing - The metal and its alloys: More than 90 percent of the manganese produced goes into metallurgical applications, the pure metal being used in copper and aluminum alloys and ferromanganese and silicomanganese employed in steel and cast iron. Most manganese is consumed as high-carbon ferromanganese for addition to carbon steels. In steels of lower carbon content, the medium- and low-carbon ferroalloy and even electrolytic manganese …

Manganese processing | Britannica

The primary product of the smelting process outlined above is a carbon-saturated ferroalloy containing 76 to 80 percent manganese, 12 to 15 percent iron, up to 7.5 percent carbon, and up to 1.2 percent silicon. It can be produced by two methods. In the first, ores are selected on the basis of their acidity so that, on smelting, 70 to 80 percent of the manganese is recovered in the melt while a slag containing …

processing equipment for manganese alloy

In the smelting of various grades of manganesebased alloys there are certain requirements for the manganese content of the ore and the ratio of ferromanganese Manganese Ore Processing line At Hengcheng we provide more than just processing equipment but constantly strive to assist you in achieving overall business excellence This. Learn More

equipment suppliers for manganese processing

A wide variety of manufacturers distributors and service process equipment metalworking mining and mineral processing stone and nuclear. Get Price ; Links Gekko. Twelve major mineral processing companies and the University of Austmine is Australia s leading industry association representing the Mining Equipment manganese and manganese alloy production industrial and metallurgical . Get …

processing equipment for manganese alloy …

processing equipment for manganese alloy Aluminum processing - The metal and its alloys | - Aluminum processing - The metal and its alloys: A ductile, silvery white metal usually with dull lustre owing to a surface film of Superpure aluminum has many applications: in stone equipment, in reflectors, as a catalyst in making gasoline, in fine jewelry .

Manganese Ore Processing Plant | Mining …

1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 mining single-shaft vibrating screen, FG -12 high-grade spiral classifier. 2 Existing problems in the manganese mining process

The Recovery of Chrome and Manganese Alloy Fines from Slag

For some time spirals have been the process equipment chosen to recover metal in the size range 0.15 to 3mm from ferrochrome and silico/ferro manganese slags. Recoveries of metal obtained using spirals are usually about 70%. Spirals are also difficult to control.

Alloy Process Equipment, Inc. | Pressure Vessel & …

Alloy Process Equipment, Inc. is a full service manufacturer of custom high quality ASME pressure vessels and process equipment. Incorporated in 2007 we have a successful history of quality workmanship and on-time deliveries with competitive pricing. From conception to installation we are equipped to provide you with engineering, design, project management, quality control, and fabrication ...

Ferroalloys - an overview | ScienceDirect Topics

The furnaces used for these processes usually have high power (>16 MVA) and the reducing agents are carbon materials (coke, char, charcoal, anthracite coal). Batch processes use a certain amount of charge material for the same heat. The charge loaded into the furnace is completely melt, leading to the reduction of the elements.

Electrochemical Behaviors of MnO2 on Lead Alloy …

The electrochemical performances of deposited MnO2 on lead alloy anode by pulse current (PC) and direct current (DC) electrodeposition in manganese sulfate solution were investigated by performing measurements of galvanostatic polarization, cyclic voltammetry (CV), and Tafel tests. The composition and morphology of MnO2 were observed by X-ray diffraction (XRD), X-ray photoelectron spectroscopy ...