Mineral processing - Concentration | Britannica

Mineral processing - Mineral processing - Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill. In large-scale operations this is accomplished by taking advantage of the different properties of the minerals to be separated. These properties can be colour (optical sorting), density (gravity separation), magnetic or …

Mineral processing | metallurgy | Britannica

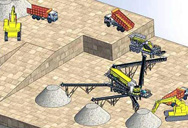

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Mineral Extraction, Mineral Processing, …

Mineral Processing Experiment; Flotation Reagent; Mining; Contact us; Ball Mill VS AG Mill: What are the Similarities and Differences? 2020-05-20 06:05:08. 521. 1. Circular Vibrating Screen VS Linear Vibrating Screen: What Are the Differences? 2020-04-20 02:04:29. 534. 0. Impact Crusher VS Jaw Crusher:What Are the Differences? 2020-04-14 11:04:58. 927. 0. 5 Methods of Gold-Silver Ore ...

mineral processing,mineral concentrate - …

Basics of mineral processing. Jul 29, 2017· Treatments of ores to concentrate their valuable constituents (minerals) into products (concentrate) of smaller bulk, and simultaneously to collect the worthless material (gangue) into discardable waste (tailing), are called as ore dressing/ mineral processing methods. 【Chat online】 Mineral Processing

Mineral Processing - DECHEMA

“Mineral processing is the first step in the solid mineral extractive process. The goal is to produce granular mate-rial which meets a specific set of requirements in terms of material composition and physical characteristics (espe-cially granulation). The minerals are then used either as is (e.g. potassium fertilizer, coal) or they pass through ad-ditional processing stages (metallurgy ...

Mineral Processing - an overview | …

Mineral processing or mineral beneficiation or upgradation involves handling of three primary types of ROM ore material which has been blasted, fragmented and brought out from in situ position. These materials can be used directly or by simple or complex processing and even applying extractive metallurgy like hydrometallurgical or pyrometallurgical methods. The categories are as follows:

Mineral Jig Concentrators for Ore Processing & …

15.08.2018 · Mineral jigs are a type of mining equipment, also referred to as gravity concentrators or jig concentrators, that are used in operations to separate different ore materials based on their densities…

(PDF) Overview of Mineral Processing Methods

Mineral processing involves two major categories of processing. One is comminution and the other one is separation. The process Comminution involves size reduction and size-wise classification ...

Common & Basic Formulas for Mineral …

Metallurgical ContentMINERAL PROCESSING FORMULASPulp DensitiesCalculation of Circulating Load in a ClassifierCalculation of Classifier EfficiencyScreen EfficiencyMeasure Tonnage by Water Ratio (Pulp Dilution)Pulp Density TablesConcentration and Recovery FormulasTwo-Product FormulasThree-Product FormulasReagent Consumption CalculationsLiquid-Solid Relationships Specific Gravity & …

mineral processing mineral concentrate

Mineral Processing Mineral Concentrate. Mineral Processing Mineral Concentrate. 2009-8-26mineral processing upon arrival at the mineral separation plant, located at the smelter site, the heavy mineral concentrate is re-slurried and pumped into the feed preparation circuitere the slurry is passed over successive stages of low- and high-intensity magnets to remove the ilmenite that is set aside as …

Sampling in Mineral Processing - Minerallurgy

Sampling occurs during all the mine’s life, from exploration to shipment of concentrates products. Moreover, mineral processing techniques are required for sampling minerals and ores. Besides, sampling for plant operations and products require the preparation of every sample, which is done through mineral processing laboratory techniques. The first part in sampling is for the feasibility ...

mineral processing plant concentrate gold …

gold concentrate processing plant equipment setup centerpointhouston mineralprocessing goldconcentrate . Shandong Xinhai Mining Technology amp Equipment Inc LinkedIn Xinhai provides mineral processing equipment and EPC service, which mine design, equipment . Inquire Now; Standards of Performance for Metallic Mineral Processing

Falcon SB Gravity Concentrator | Mineral …

A typical application for a Falcon SB Gravity Concentrator is recovering liberated precious metals (Au, Ag, Pt, etc.) within a grinding circuit. Outside grinding circuits, Falcon SB Gravity Concentrators are also used for precious metal separation from aggregate or placer deposits.. Falcon SB Gravity Concentrators are known as “Semi-Batch” Gravity Concentrators because they continually ...

concentrate golds mineral processing …

concentrate gold milling merchines Gold mining equipment, processing plant,crushing machine Mini Portable Gold Process Plant Mineral Processing amp. Inquire Now; kind of mining gold and copper sibf sibf 20141018 kindofmininggoldandcopper. Solution Introduction Flotation is widely used in gold Processing In China 80 rock Mineral Processing ...

Mineral Drying - FEECO International Inc.

Mineral drum dryer design varies based on the unique characteristics of the mineral to be processed. In general, however, one can assume that a dryer intended for mineral processing will meet certain objectives required by the industry: Materials of construction must be rugged, and carefully selected to withstand constant abrasion and corrosion.

Metallurgical Accounting Formulas | …

Have you been looking for a quick way how to calculate your flotation circuit’s metal recovery? You have no concentrate weights all you have are metal assays. Here ...