“Computer Aided Design of Jaw crusher”

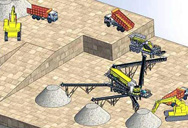

crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock. They follow “crush using compression” mechanism.

How to Build a Rock Crusher | Home Guides | SF Gate

Jul 21, 2017 · This particular kind of rock crusher is perfect for homeowners or amateur prospectors. Using your tape measure and permanent marker, measure and mark the center of the iron board. Center the 4-inch...

Simple Can Crusher : 4 Steps - Instructables

Simple Can Crusher: This instructable is how to make a very simple can crusher. This is a 15 minute approx build. All you need is some scrap 2x4s and a hinge and some screws. While researching DIY can crushers I came across several different methods from heavy duty,…

A Not-Simple DIY Can Crusher - Mikes Inventions - YouTube

Oct 03, 2017 · https://mikesinventions.etsy.com I show you how I used a bit of PVC pipe, some wood, and steel bar to create a (relatively) simple, yet effective can crusher...

Build Your Own Destemmer-Crusher - WineMakerMag.com

To build the crusher at the end of the bottom box (with the 15 inch/38 cm open end), I built a 17 x 10-inch (43 x 25-cm) box out of 1⁄2-inch plywood that had a funnel shape to it. To do this, I cut two pieces for the front and back, and then took one piece on each side and angled it …

How to Make an Aluminum Can Crusher: Ultimate DIY Hacks ...

Jul 28, 2009 · An aluminum can crusher, as its name suggests, is used to crush or smash empty aluminum cans to the smallest possible size in order to recycle them. The method put to use depends on the type of can crusher you use. Some of these crushers are designed to crush cans by applying force from both sides, while some smash the can from above.

How to Build a Serious Apple/Grape/Fruit Crusher on the ...

It doesn’t really crush the fruit so much as purée it – which is a highly desirable result when you’re trying to press fruit to make wine or cider of any kind. Being the cheap ass that I am, my disposal is a 3/4 HP erator that I picked up on Kijiji for about half of the cost of new.

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT …

to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysis.

Crusher (Immersive Engineering) - Official Feed The Beast Wiki

Aug 19, 2019 · This page is about the Crusher added by Immersive Engineering. For other uses, see Crusher. The Crusher is a 3x5x3 multi-block added by Immersive Engineering. It is used for crushing Ores into Grit (Dusts), which is more efficient than normal smelting. The Crusher …

Make an air cylinder driven can crusher

Can crusher leaking problem. by Doug McCrary (San Diego, CA USA) I got the primary air filter added to the main air. The valves are both “off”, and there is very little air reserve between the (red handle) valves and the crusher switch/cylinder. If I were doing an air brake check on a vehicle, 3psi loss in one minute would be acceptable.

HOW TO - Build the "Ultimate Beer Can Crusher" | Make:

Aug 03, 2006 · Ed Nauman @ Design News shows you how to build your own Ultimate Beer Can Crusher, complete instructions, AutoCAD drawing and Visual Basic files included – “For the gadget freak who thinks he has everything, here’s Ed Nauman’s microprocessor-controlled, pneumatic-actuated can crusher.Great for parties, it consists of a pneumatic ram, precision bore crushing cylinder with …

How to Build a Power Pop Can Crusher From PVC | Hunker

Measure the dimensions of the open sides, and cut additional lengths sized to fit. Place these over the open ends, drilling them into place. Drill another hole through the center of one side, through which to feed the air hose. This will finish the box to hold your can crusher.

Analyzing the operation and design of a Jaw Crusher using ...

The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod. Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machine.

Homemade Glass Crusher | eHow

Crushed glass is easy to make, and you can use it for hundreds of projects ranging from art to home decor. The most common term for small pieces of crushed glass is frit, which ranges in size and texture based on the method of glass crushing. You can use crushed glass in jewelry, beads, lamps and ...

The Best Aluminum Can Crusher of 2020 - Your Best Digs

Sep 21, 2020 · A fter spending over 40 hours and crushing over 1,000 soda cans we determined that Easy Pull‘s auto-dispensing can crusher is the best can crusher. The Easy Pull proved to be quick, simple to use and very affordable. Additionally, its design for crushing cans virtually eliminates the risk of cutting your fingers on a ragged edge.

Jaw Crusher - ScienceDirect

Jan 01, 2016 · The factors of importance in designing the size of primary crushers, such as a jaw crusher, are: (4.1) Vertical height of crusher ≈ 2 × Gape (4.2) Width of jaw > 1.3 × Gape < 3.0 × Gape (4.3) Throw = 0.0502 (Gape) 0.85 where the crusher gape is in metres.