Froth Flotation Process - Detailed Explanation …

In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer. Flotation is the process of separation of beneficial minerals from a mixture by creating froth …

Copper Flotation - Elmhurst College

Ore Concentration by Froth Flotation Remember that only 0.67% of the ore is copper. The copper minerals and waste rock are separated at the mill using froth flotation.

Flotation Froth - an overview | ScienceDirect Topics

The crushed ore is grinded in ball mills to −74 μm size. The ore is processed by froth flotation comprising rougher and scavenger cells. The common reagents for copper ore flotation are xanthates as collector, pine oil as frother, sodium cyanide as depressant, and lime to maintain slurry alkalinity. The concentrate in the form of froth and slurry contains +20% copper. It is thickened in a rake-type unit …

1 Froth Flotation – Fundamental Principles

Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry.

(PDF) A Review of the Flotation of Copper Minerals

The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground mines) is of great commercial importance....

Froth Floatation Process - YouTube

Follow us at: https://plus.google.com/+tutorvista/ Check us out at http://chemistry.tutorvista.com/inorganic-chemistry/metallurgy.html Froth Floatation Proce...

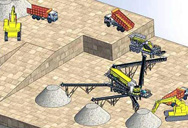

Copper Sulfide Flotation - Mineral Processing & …

Copper Sulfide Flotation Circuit Beneficiation of Copper Sulfide by Flotation Copper, due to the present world demand and price, is of foremost interest to the mining industry. Many new properties are either in the process of being brought into production or are

Copper ore flotation process - YouTube

The flotation machine is used for the separation of the nonferrous black metal as well as the separation of the non-metallic materials such as the coal fluor...

Froth Flotation - YouTube

Heres a short teaser video of our metallurgical lab technicians replicating the froth flotation process. The full video will be coming soon!

Froth Flotation of Copper Ore - Home | Facebook

Froth Flotation of Copper Ore. 178 likes. Froth Flotation

Abstract On Froth Floatation Method Copper Ore

Ore concentration by froth flotation remember that only 0.67 of the ore is copper.The copper minerals and waste rock are separated at the mill using froth flotation.The copper ore slurry from the grinding mills is mixed with milk of lime simply water and ground-up limestone to give a basic ph, pine oil yes, it comes from trees- a by.

Froth Flotation Process For Concentration Of …

Iron ore concentration process flotation froth flotation is an important concentration process this process can be used to separate any two different particles and operated by the surface chemistry of the particles in flotation bubbles are introduced... Crushing And Concentration Of Copper Ore By Froath...

Froth Flotation Process For Copper - …

Froth flotation grinding mills copper ore ball mill process. The copper minerals and waste rock are separated at the mill using froth flotation The copper ore slurry from the grinding mills is mixed with milk of lime simply water and groundup limestone to give a basic pH pine oil yes it comes from trees a byproduct of stone mills to make bubbles an alcohol to strengthen the bubbles and a ...