Dry Iron Ore Beneficiation | Iron Ore Separation - …

Magnetic separation is typically used in the beneficiation of high grade iron ores where the dominant iron minerals are ferro and paramagnetic. Wet and dry low-intensity magnetic separation (LIMS) techniques are used to process ores with strong magnetic properties such as magnetite while wet high-intensity magnetic separation is used to separate the Fe-bearing minerals with weak magnetic …

Beneficiation of Iron Ores – IspatGuru

Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material. Grade of iron ore is usually determined by the total Fe content in the ore. Run of mines ores after dry or wet …

Iron Ore Beneficiation - University of Newcastle

Iron Ore Beneficiation Introduction. Iron Ore Beneficiation increases the grade of iron whilst maximising recovery and reduces the content of ultrafine low grade slimes to maximise return on investment from the mining process prior to sale or further refining in the iron making process. Existing technologies are deficient and hence the goal is to develop innovative approaches in dry …

Dry Beneficiation Of Iron Ore | Dry Beneficiation …

Dry Iron Ore Beneficiation Iron Ore Separation St Iron ore beneficiation using magnetic separation dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits stet has evaluated several iron ore tailings and run of mine ore

Beneficiation Of Iron Ore In Dry Process To …

Beneficiation Of Iron Ore In Dry Process To Remove Silica. This invention refers to a water-less extraction process to collect clay, silica and iron ore from tailings taken from tailings dams and deposits by drying, dry sifting, density separation, mechanical friction separation, air classification separation, milling and magnetic separation. This is achieved by using pieces of …

Processes for Beneficiation of Iron Ores – IspatGuru

The term beneficiation in regard to iron ores encompasses all of the methods used to process ore to improve its chemical, physical and metallurgical characteristics in ways which makes it a more desirable feed for the iron making furnace. Such methods include crushing and grinding, washing, filtration, sorting, sizing, gravity concentration, magnetic separation, flotation along with …

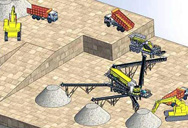

Dry Iron Ore Beneficiation Iron Ore Separation St

Dry Iron Ore Beneficiation Iron Ore Separation St Sand making plant is a professional production line to produce building sand and stone. It can make a variety of rock, sand and gravel, river pebbles into various size construction sand, sandy uniform particle size

Ore Beneficiation - an overview | ScienceDirect …

Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated. This screening is an essential step prior to their separation into ore product and waste rock. …

New dry iron ore processing technology …

25.05.2016 · Brazilian company New Steel have developed a new dry iron ore tailings process to make mining more environmentally sustainable. It involves the dry recovery of iron ore fines and super fines from mining wastes, low grade run of mine (ROM), or compact itabirite.

Direct reduced iron - Wikipedia

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) to iron by a reducing gas or elemental carbon produced from natural gas or coal.Many ores are suitable for direct reduction. Direct reduction refers to solid-state processes which reduce iron oxides to metallic iron at temperatures below the melting ...

Dry Process Of Magnetite Iron Ore Beneficiation

Iron Ore Dry Beneficiation. Iron ore dry beneficiation plant Drying Machine used for ore beneficiation cement grinding plant Mining And Crushing Drying Machine is used for roasting process in the mine ore beneficiation cement grinding plant and sand making line Drying Machine Overview Drying Machine mainly consists of revolving part raising stuff plate driving device supporting device

dry grinding beneficiation process for iron ore

iron ore dry grinding mill china. iron ore beneficiation dry process thegurukulinstitutein dry iron ore beneficiation process dry iron ore beneficiation process As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions for any size . Chat Online

iron ore dry beneficiation plant - joerg-steinbach …

iron ore dry beneficiation plant Apr 03 2014 · Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 70 iron hematite or Fe3O4 72 iron magnetite Ores are normally

Iron Ore PRICE Today | Iron Ore Spot Price Chart | …

Iron Ore Commodity. 121.53 0.09 0.07%. Official Close 10/19/2020 MI Indication. Add to watchlist Trade Now. News . Financial Times 1 hrs ago. BHP and Vale enjoy boom in iron ore demand. Financial ...

Iron Ore | 2007-2020 Data | 2021-2022 Forecast | …

Iron Ore increased 26.50 USD/MT or 28.80% since the beginning of 2020, according to trading on a contract for difference (CFD) that tracks the benchmark market for this commodity. Historically, Iron Ore reached an all time high of 200 in November of 2007.

Beneficiation Process Of Iron Ore Hematite Dry …

Beneficiation of iron ore this also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation all such plants are large tonnage operations treating up to 50000 tons per day and ultimately requiring grinding as fine as minus 500mesh for liberation of the iron minerals from the siliceous gangue

Dry Beneficiation Of Iron Ore For Sale In Thailand

About Ore Beneficiation The iron ore produced from Iron Ore Mine is rich in iron content with low impurities The iron ore is recovered in the form of lumps 40 and fines 60 The iron ore produced from the mine is transported to the crushing and dry screening at …

Iron Ore Crusher Dry Benification Crushing Plant

Iron Ore Dry Benification Plant Crusher Unit. 2019-11-25 · Iron Ore Benification Plant For Sale Clubaerodes. iron ore benification plant for sale. portable crusher. crusher manufacturer crushing plant rock crusher in2011 hot sale high efficiency mini jaw crusher hematite iron ore beneficiation …