Electrorefining of Copper - Universidade Federal do Rio ...

Electrorefining of Copper 1. Electrorefining – General Introduction In an electrorefining process, the anode is the impure metal and the impurities must be lost during the passage of the metal from the anode to the cathode during electrolysis, i.e. the electrode reactions are, at the anode: M → Mn+ + ne-and at the cathode: Mn+ + ne-→ M

Copper Electrorefining - Last step - Elmhurst …

Copper Electrorefining - Last step. The end result of of the copper smelter operations is anode copper which is 99% pure (see graphic on the left). An example where copper is further purified is at the Asarco electrolytic plant in Amarillo, Texas. The 99% pure copper from the anode furnace is cast into 750-pound, 3-inch thick, rectangular slabs called anodes. ...

Electrorefining Chemistry Tutorial - AUS-e-TUTE

Electrorefining Copper. During the electrorefining stage of copper production, a series of impure copper anodes and thin starter sheet cathodes (such as thin copper foil) are suspended in a tank. The electrolyte containing the copper ions flows through tank. The electrolyte is often copper dissolved in sulfuric acid which produces an aqueous solution of copper ions.

Copper electrowinning: theoretical and practical design

COPPER ELECTROWINNING: THEORETICAL AND PRACTICAL DESIGN 213 Introduction The electrowinning of copper ions derived from leaching, or solvent extraction is a significant contributor to the global copper commodity supply. The process of electrolysis for copper was first developed in the late 19th century and despite numerous advancements in technology the

Electrolytic Refining - Meaning, Electrorefining …

Copper is usually mined from its coal known as blister copper. It is about 98 to 99 per cent pure. However, the electro-refining process can easily make it 99.95% pure which makes it a good product to be used in electrical components. A block of impure copper is taken as an anode or positive electrode. Copper sulfate which is acidified with sulfuric acid is used as a graphite …

Applications of Copper Electrowinning - …

The electrowinning of copper is an electrolytic process that uses electricity to recover dissolved copper from solution as copper plate, also known as ‘cathode’. Cu 2+ (aq) + 2e - -->Cu (s) (E 0 = +0.34V)

Electrorefining Copper - Metallurgist & Mineral …

Table of ContentsApparatus and Experimental TechniquesRotating Electrode CellsSingle Channel CellsMulti-channel CellResultsRotating Electrode CellsRing ElectrodesCylinder ElectrodesSingle-Channel CellSynthetic Electrolyte TestsTankhouse Electrolyte TestsComparison with Industrial Refining CellsMultichannel CellInitial Electrolysis StudiesFiltration and Settling …

Electrowinning Copper Chemistry Tutorial

Electrowinning Copper Key Concepts. Electrowinning refers to the process of using electrolysis to extract a metallic element from the compounds in its ore. Copper occurs on Earth both as native copper (the uncombined element, Cu), and in ores (copper compounds, or mixtures of compounds, from which copper metal can be extracted profitably). Copper ores are usually copper oxides, copper …

Electrowinning - Wikipedia

Electrowinning is the oldest industrial electrolytic process. The English chemist Humphry Davy obtained sodium metal in elemental form for the first time in 1807 by the electrolysis of molten sodium hydroxide. Electrorefining of copper was first demonstrated experimentally by Maximilian, Duke of Leuchtenberg in 1847.

(PDF) Copper electrowinning - 2013 world …

operations employ thiourea and avitone, similar to the copper electrorefining industry. Most operations operate with 20 to 30 mg/L Cl in the electrolyte. Chloride ions . …

Electrowinning - an overview | ScienceDirect Topics

The cathodic copper deposit is similar to that from electrorefining. Industrially, the electrodes are about a square meter each side and the plating takes place at about 2 V and 200–300Am −2 . The cathodes are removed about every seven days, the copper is stripped from them, and the stainless steel mother blanks are returned to the electrolytic cell for further electrolysis.

Copper Electrorefining and - GBV

/ Vol. 5 / Copper electrorefining and electrowinning : in honor of Charles Cooper ; held in conjunction with the 37th Annual Hydrometallurgy Meeting ; symposium Subject: Montréal, Canadian Institute of Mining, Metallurgy and Petroleum, 2007 Keywords: Signatur des Originals (Print): RO 8313(6,5). Digitalisiert von der TIB, Hannover, 2010. Created Date: 6/30/2010 …

Electrorefining - an overview | ScienceDirect Topics

Copper from electrorefining, after melting and casting, contains less than 20 ppm impurities, plus oxygen which is controlled at 0.018–0.025%. Electrorefining entails electrochemically dissolving copper from impure copper anodes into an electrolyte containing CuSO 4 and H 2 SO 4 and then electrochemically depositing pure copper from the electrolyte onto stainless steel or copper …

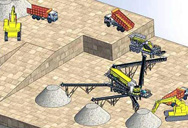

Copper extraction - Wikipedia

Copper extraction refers to the methods used to obtain copper from its ores.The conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.. As in all mining operations, the ore must usually be beneficiated (concentrated).

Electrowinning 101: What is electrowinning?

Another similar process is electrorefining which is strictly used in refining applications to improve the purity of the metals. Both processes use electroplating and are used to purify non-ferrous metals such as copper and silver. A conventional electrowinning unit consists of a tank, rectifier and pump. Cathodes and anodes are aligned inside the tank. The pump fills the tank with …

(PDF) Predictive Current Controller for Thyristor ...

Predictive current controller for thyristor rectifiers in copper electrorefining and electrowinning industry is presented in this paper. Due to their reliability and cost-effectiveness, high power ...

WCLN - Electrorefining - YouTube

06.12.2014 · The process of electrorefining using an impure copper anode and a pure copper cathode is explained using half-reactions and their relative positions on the standard reduction potential table. http ...

ELECTROREFINING OF GOLD PDF - PDF Love Pink

ELECTROREFINING OF GOLD PDF - Electrowinning, also called electroextraction, is the electrodeposition of metals from their ores The most common electrowon metals are lead, copper, Skip to content PDF Love Pink. Search. ELECTROREFINING OF GOLD PDF. Posted on November 28, 2019 by admin. Electrowinning, also called electroextraction, is the …

Copper Recovery - INDUSTRIAL SCRAP …

Copper Recovery is a manufacturer of wire and cable recycling equipment, offering sales and service worldwide. We also act as agent or representative for some of the finest European manufacturers of recycling machinery. Most recently, we infused our knowledge and know-how gained over the last 18 years of cable recycling, combined it with a proven platform, added in a …

Electrorefining Of Copper Process - …

Electrorefining electrorefining is an electrolytic process that involves anodically dissolving a metal at the positive electrode in a cell and simultaneously redepositing the same metal at the negative electrodehe first patents for metal electrorefining were for copper …